Property managers know the frustration all too well: discovering a loose piece of cladding or deteriorating sealant on a building’s exterior, only to be quoted thousands for scaffolding just to take a proper look. Meanwhile, pedestrians continue to walk beneath potentially hazardous façades whilst owners grapple with the logistics and costs of traditional inspection methods.

Rope access has changed this landscape dramatically. IRATA-certified technicians can now reach any point on a building’s exterior with remarkable efficiency. They conduct thorough inspections without the scaffolding headaches or street closures that once made façade assessments such a complex undertaking.

Continue reading to explore how this approach is helping building owners maintain safer properties whilst keeping costs manageable.

The Reality of Modern Façade Inspection Needs

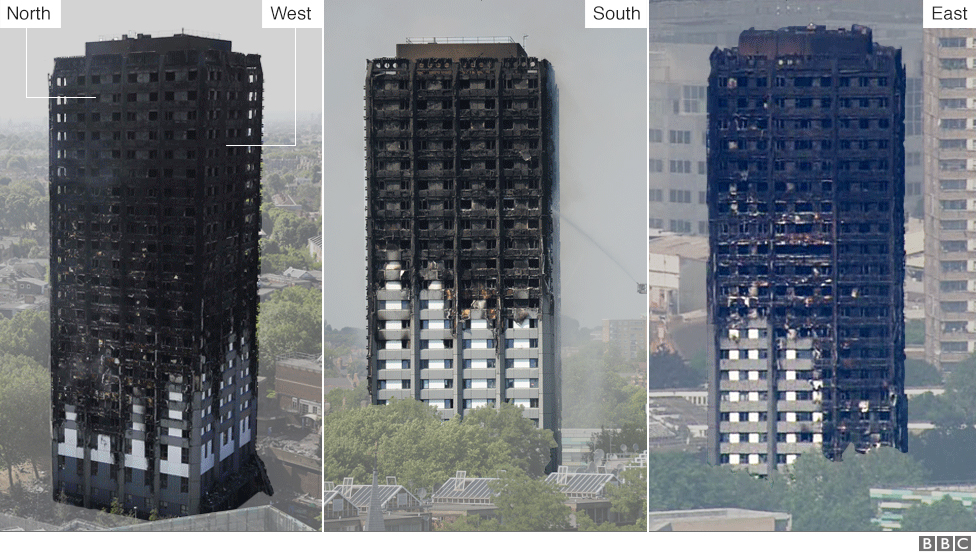

Building regulations have become increasingly strict regarding façade safety, especially in response to high-profile incidents such as the Grenfell Tower fire. The tragic event began in the kitchen of a fourth-floor flat, and within minutes, flames rapidly spread upwards and across the eastern side of the building before engulfing the north face of the tower.

One of the primary factors behind the rapid spread of the fire was the external cladding, which consisted of aluminium sheets bonded to a polyethylene core. Reports from the public inquiry revealed that this cladding contained a highly combustible polyethylene polymer filler, which melts, drips, and flows at high temperatures, releasing large amounts of energy during combustion. Additionally, other flammable materials, including polyurethane polymer foam insulation from an earlier refurbishment, were present and may have further contributed to the fire’s intensity.1

These findings emphasise the critical need for regular safety assessments. Inspections should never be treated as mere box-ticking exercises but the essential measures for identifying real risks before they compromise people’s safety.

A proper façade inspection examines everything from the condition of external cladding and structural elements to the integrity of window seals and weatherproofing systems. The inspector’s trained eye can spot early signs of deterioration that might go unnoticed for months or years, gradually worsening until they become expensive emergency repairs or safety hazards.

What makes these inspections particularly valuable is their role in preventive maintenance. Rather than waiting for visible problems to emerge, regular assessments help building owners stay ahead of issues, plan repairs during favourable weather, and coordinate with other maintenance activities.

Why Rope Access Makes Sense for Inspecting Building Exteriors

Anyone who’s worked with traditional access methods understands their limitations. Scaffolding takes weeks to install, blocks pavements, and costs a fortune. Cherry pickers struggle with complex building shapes and weather restrictions. Cranes require road closures and extensive planning permissions.

Rope access technicians, however, can be examining your building’s façade within hours of arriving on site. They move with precision around architectural features, getting close-up views of specific problem areas that other methods might struggle to reach. This flexibility proves invaluable when dealing with London’s diverse building stock, from Victorian terraces with intricate detailing to modern towers with challenging geometries.

Commercial and residential rope access services adapt to virtually any building configuration, whether you’re dealing with a listed building’s delicate stonework or a contemporary office block’s curtain walling system.

The practical advantages include:

- Setup completed in hours rather than weeks

- Minimal disruption to building users and surrounding businesses

Access to previously unreachable areas of complex façades - Significantly lower environmental impact than heavy machinery

- Exceptional safety record backed by rigorous IRATA standards

The Financial Benefits That Actually Matter

Most building owners have experienced the sticker shock of scaffolding quotes. A comprehensive façade inspection using traditional methods can easily run into five figures when you factor in erection, hire periods, and dismantling costs. The knock-on effects—lost parking spaces, disrupted businesses, and extended timelines—add further hidden costs.

Rope access eliminates most of these expenses. Teams can complete detailed inspections in a matter of days, rather than weeks, with costs typically 60-70% lower than those of scaffolding alternatives. More importantly, the speed of deployment means problems get identified and addressed quickly, before they escalate into major structural issues.

There’s another financial benefit that’s often overlooked: the ability to combine inspection work with immediate minor repairs. For instance, when glazing maintenance issues are spotted during an inspection, technicians can often address them on the spot, avoiding the need for separate access operations later.

Safety Standards That Protect Everyone

The rope access industry has developed some of the most rigorous safety protocols in the construction sector, and for good reason. Working at height demands absolute attention to detail, proper training, and fail-safe systems.

IRATA certification ensures that technicians understand both the technical aspects of rope work and how to conduct thorough inspections while maintaining safety standards. Every operation begins with comprehensive risk assessments tailored to the specific building and inspection requirements.

Teams work with designated safety supervisors, maintaining constant communication throughout the work. Equipment undergoes regular testing and replacement schedules that exceed industry standards. Such a systematic approach has resulted in rope access achieving one of the lowest accident rates in high-risk industries—a record that provides reassurance to building owners and occupants alike.

Documentation That Serves Multiple Purposes

A façade inspection is only as good as the report it produces. Professional rope access inspectors provide detailed documentation that effectively serves building owners, insurers, and regulatory bodies.

Modern reporting combines high-resolution photography with precise defect mapping, creating visual records that clearly communicate the building’s condition. Beyond ticking compliance boxes, these reports become valuable planning tools for maintenance teams and budget forecasters.

Building surveying services often work alongside rope access inspections, providing additional technical analysis that helps building owners understand what needs attention, why, and when repairs should be prioritised.

The documentation creates a historical record of façade condition over time, enabling more accurate forecasting of future maintenance requirements and supporting strategic planning for major refurbishment projects.

Working with British Weather

London’s climate is getting worse. Summers are getting warmer and drier, whilst winters are getting wetter. Extreme weather, such as heavy rainfall and heat waves, is also becoming more common.2

These unpredictable weather conditions present unique challenges for exterior building work. Yet, rope access operations can proceed safely in situations that would halt other access methods. While wind limits apply to all height work, experienced rope access teams can often work in moderate conditions that would prevent crane or platform operations.

Even light rain doesn’t necessarily prevent inspections, though it may affect photographic quality or limit certain work activities. Professional operators continuously assess conditions and adjust programmes accordingly, ensuring both safety and inspection quality remain uncompromised.

This weather flexibility proves particularly valuable given London’s unpredictable climate. Rather than waiting for extended periods of perfect weather, rope access teams can respond quickly to suitable conditions, completing inspections when the opportunity arises.

Making the Right Choice for Your Building

Façade inspections have become an essential responsibility for building owners, balancing safety obligations with practical constraints like budgets and operational requirements. Rope access technology addresses these challenges effectively, offering a solution that prioritises both thoroughness and efficiency.

The evidence speaks clearly: reduced costs, minimal disruption, enhanced safety, and superior access capabilities make rope access the logical choice for modern façade inspection programmes. As safety regulations continue to emphasise proactive maintenance, this approach will likely become even more central to responsible building management.

For building owners seeking comprehensive façade assessments without the traditional constraints and costs associated with scaffolding, rope access is a practical and professional solution that delivers results when needed most.

References

- BBC News. (2019). Grenfell Tower: What Happened. Retrieved from https://www.bbc.com/news/uk-40301289

- Greater London Authority. (n.d.). Climate Change and Weather. Retrieved from https://www.london.gov.uk/programmes-and-strategies/environment-and-climate-change/climate-change/climate-change-and-weather