Silos store everything from grain to cement, chemicals to coal. But these giants need care. Regular maintenance keeps them functioning safely and efficiently.

Traditional access methods fall short when dealing with silos. Scaffolding takes weeks to erect around these towering structures. Mobile elevated work platforms can’t reach the heights required. Cranes are expensive and weather-dependent.

At Rope Access in London (RAIL), we’ve pioneered rope access techniques that allow our industrial specialists tackle oil and gas rigs with the same precision we bring to silo work.

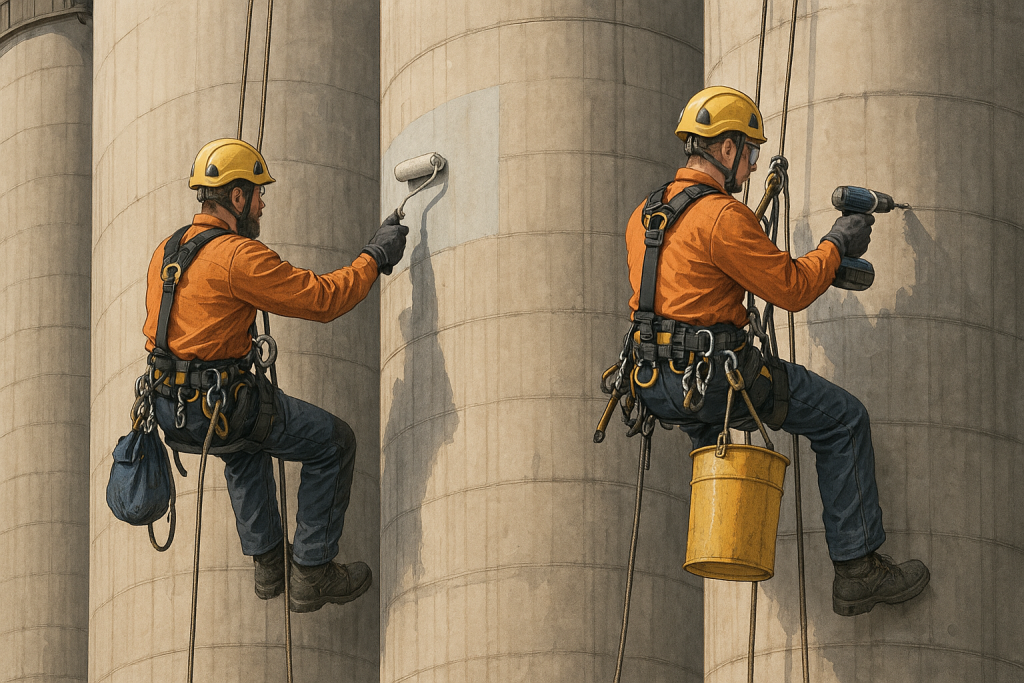

The beauty of rope access lies in its simplicity. It only requires skilled technicians and minimal equipment.

We’ve completed countless silo projects across the UK, from routine inspections to complex structural repairs.

Why Is Rope Access the Preferred Method for Silo Maintenance?

Speed defines rope access work. Where scaffolding takes weeks, we deploy in hours.

Traditional access methods require extensive planning and site preparation. We arrive, assess, and begin work the same day.

Cost savings are immediate and substantial. Scaffolding rental alone can cost thousands per week. Add labour for erection and dismantling, plus lost production time, and costs spiral. Our rope access teams eliminate these overheads entirely.

Flexibility in Complex Environments

Silos rarely exist in isolation. They’re surrounded by pipework, conveyor systems, and other structures. Scaffolding struggles in these confined spaces. Our technicians navigate around obstacles with ease.

Weather becomes less of a factor, too. We continue working in conditions that halt traditional access methods. Of course, we maintain strict weather protocols for safety.

At RAIL, our industrial experience spans wind turbines and offshore platforms. These environments have taught us to work efficiently in challenging conditions. We bring this expertise to every silo project.

Minimal Operational Disruption

Production rarely stops for maintenance when you choose rope access. Traditional methods often require plant shutdowns, area evacuations, or production delays. We work around ongoing operations safely.

Our external painting services demonstrate this principle perfectly. While competitors require scaffolding that disrupts site traffic, we complete painting projects with minimal ground-level impact. The same applies to waterproofing and cladding work.

What Are the Essential Safety Protocols for Silo Rope Access Work?

Silo interiors present unique hazards — grain dust can explode, chemical residues prove toxic.

We never enter a silo without proper atmospheric testing. Gas monitors check for explosive gases, toxic substances, and oxygen levels. Ventilation systems run continuously during interior work.

Our specialist technicians train specifically for these environments. A welder working inside a grain silo faces different risks than one working on a building facade. We prepare for every scenario.

Working at Extreme Heights

Some silos reach heights exceeding 100 metres. At these elevations, weather conditions change rapidly.

Our building surveying experience serves us well here. We’ve assessed structures across London, from historic buildings to modern skyscrapers. Height doesn’t intimidate us — it challenges us to excel.

We train extensively in high-angle rescue techniques. Self-rescue capability is mandatory for all team members.

Conclusion

Rope access has revolutionised silo maintenance and repair. Traditional methods simply cannot match the speed, safety, and cost-effectiveness we deliver. Every project reinforces why major operators choose rope access over alternative methods.

At RAIL, we provide solutions. Our specialist technicians combine trade expertise with rope access skills to deliver exceptional results. From routine cleaning to complex structural repairs, we approach every project with the same commitment to excellence.

Whether you need building maintenance, external painting, or specialist industrial services, we have the expertise and equipment to deliver. Contact us today to discover how rope access can transform your silo maintenance programme!

Frequently Asked Questions

How long does rope access training take for silo-specific work?

Initial rope access certification requires three levels of training, typically completed over several months. Silo-specific training adds confined space entry certification, atmospheric monitoring, and emergency response procedures. Most technicians need 6-12 months to become fully competent for independent silo work.

Can rope access teams work during silo loading or unloading operations?

Generally, no. Loading and unloading create dust clouds that reduce visibility and increase explosion risks. Mechanical systems also present entanglement hazards. We typically coordinate with operators to schedule work during inactive periods, though external inspections may be possible during limited operations.

Are there silos too tall for rope access methods?

No height limit exists for rope access work, provided proper equipment and techniques are employed. However, extremely tall structures may require staging platforms for rope management and emergency response. We’ve successfully completed projects on structures exceeding 200 metres in height.