In sectors where working at height is unavoidable—be it maintenance, inspection, or construction—ensuring safety and efficiency cannot be overlooked. Traditional methods like scaffolding and aerial lifts have long been employed, but they come with limitations in terms of cost, time, and accessibility. That’s where rope access shines.

The method has been recognised for its safety and versatility, making it the preferred choice for many industries.

Keep reading to explore how rope access compares to other high-access methods, why it excels in safety, and how it meets the rigorous demands of high-risk jobs.

The Reality of Working at Height

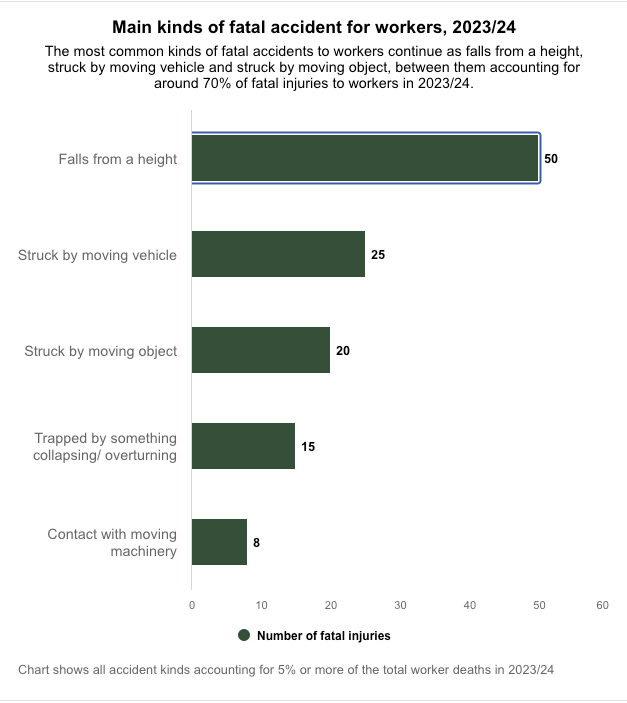

High-rise maintenance, construction, and inspections come with significant risks. Falls from height remain one of the leading causes of workplace fatalities. The Health and Safety Executive (HSE) registered 50 fatal injuries due to falls from height, accounting for 36% of all worker deaths in the UK between 2023 and 2024.

Common challenges in high-access jobs include:

- unstable structures that make traditional scaffolding impractical and dangerous

- weather disruptions, limiting work efficiency

- high operational costs, especially for temporary installations

The figures mentioned above are serious reminders of the importance of using the right access solutions. This is where rope access comes in, eliminating many of the limitations associated with traditional methods while maintaining exceptional safety standards.

Why Rope Access Outperforms Other Methods

Rope access provides a controlled and minimally invasive method for working at height. Developed from climbing and caving techniques, it offers a dynamic solution where traditional scaffolding might be impractical, expensive, or disruptive.

Rope access offers unparalleled benefits:

Precision in Challenging Environments

One of rope access’s standout advantages is its adaptability. Whether navigating complex architectural features or accessing tight corners on heritage buildings, rope technicians are trained to handle it all.

What sets rope access apart is the high level of control operators have over their movements, allowing them to work with greater precision. This is particularly useful for delicate jobs like building façade repairs, where even a small misstep could result in further structural damage or safety hazards.

Efficient Use of Time and Resources

Time is money, especially in property management and commercial contracting. Rope access helps teams meet tight deadlines without sacrificing quality or safety.

Consider a busy office block in central London. Erecting scaffolding would take days and obstruct foot traffic. Using rope access, technicians can begin work within hours, finishing tasks before tenants even notice.

Here’s how rope access cuts down operational friction:

- rapid mobilisation and demobilisation

- less site downtime

- reduced reliance on permits and road closures

For time-sensitive services like roofing maintenance, this kind of responsiveness is a game-changer.

Training, Safety, and Professionalism

It’s not just the gear that makes rope access effective—it’s the people behind it. Certified rope access technicians follow strict IRATA (Industrial Rope Access Trade Association) guidelines, which demand ongoing training, re-certification, and hours of practical experience.

When hiring rope access professionals, clients can expect:

- detailed risk assessments and method statements (RAMS)

- on-site rescue plans

- technicians with logged hours and verified qualifications

- compliance with the Work at Height Regulations 2005

Such a structured approach translates into safer worksites and higher quality outcomes—making rope access a reliable option for both one-off tasks and long-term maintenance contracts.

Environmental and Operational Benefits

Beyond its safety and efficiency, rope access also offers environmental benefits, making it a low-impact alternative to traditional access methods. Its minimal equipment requirements reduce disruption to the surrounding environment, making it particularly well-suited for sensitive locations where large-scale structures may damage surrounding ecosystems.

Additionally, rope access eliminates the need for fuel-powered machinery, significantly lowering carbon emissions. Traditional methods often rely on cranes, generators, and heavy vehicles, all of which contribute to air pollution. In contrast, rope access depends on human skill and lightweight equipment, making it a more sustainable choice for building maintenance and industrial operations.

Noise pollution is another area where rope access holds a clear advantage. Without the constant clanging of scaffolding poles or the rumble of heavy machinery, work can proceed with minimal disturbance—a crucial factor in urban environments, residential areas, and commercial spaces. Studies have shown that prolonged exposure to excessive noise can lead to hearing loss, stress, and high blood pressure, affecting both human health and wildlife. By reducing environmental noise, rope access helps maintain a quieter, healthier workspace while ensuring efficient project completion.

Conclusion

Rope access is the most efficient, cost-effective, and safest choice for working at height. With rigorous safety measures, impressive flexibility, and proven efficiency, it surpasses traditional methods like scaffolding, making it the gold standard for high-risk jobs.

For businesses seeking dependable, affordable, and eco-friendly high-access solutions, rope access remains unrivaled—offering precision, speed, and minimal disruption across industries.