The offshore oil rig worker clinging to twisted steel 100 metres above the North Sea couldn’t have imagined his industry would one day become a pioneer in workplace safety.

Back in the early boom days of petroleum extraction, workers faced extraordinary dangers with little more than their wits and questionable balance to keep them alive. The transformation from this perilous beginning to today’s sophisticated safety culture represents one of the most remarkable evolutions in industrial history.

Understanding this safety journey reveals why modern rope access techniques have become indispensable for maintaining the complex infrastructure that powers our world.

Continue reading to explore how catastrophic events shaped today’s rigorous safety standards and why industrial rope access emerged as a crucial solution for offshore maintenance challenges.

The Dangerous Early Days

Safety wasn’t even a concept when the oil and gas industry began its explosive growth in the late 19th century. Workers approached their tasks with remarkable fearlessness-or, perhaps foolhardiness-scaling derricks and platforms without harnesses, ropes, or any protective equipment. These early petroleum pioneers operated under the principle that accidents were simply part of the job.

The statistics from this era paint a sobering picture. During what historians refer to as the “Black Gold Age” of the early 1900s, workplace accidents claimed a staggering number of lives. The U.S. Bureau of Labor Statistics reported about 23,000 industrial deaths in 1913 alone, with oil and gas operations contributing significantly to this grim tally. Workers accepted these risks as the price of progress, unaware that revolutionary safety measures would eventually emerge.

Back then, industrial accidents weren’t just common–they were expected. The absence of proper communication systems, safety protocols, and emergency procedures meant that when things went wrong, the consequences were catastrophic. These harsh realities would eventually force the industry to reconsider its approach to worker protection.

The Offshore Challenge

As oil exploration moved from land to sea, new complexities emerged that traditional safety approaches couldn’t address. Offshore platforms presented unique challenges, including limited space, harsh weather conditions, and isolation from emergency services. These factors demanded innovative solutions that conventional access methods simply couldn’t provide.

The North Sea oil boom of the 1960s and 1970s highlighted these challenges dramatically. Platforms required constant maintenance, inspection, and repair work in environments where traditional scaffolding proved impractical or impossible. Wind, waves, and confined spaces made standard access methods dangerous and often unfeasible.

This period saw the birth of specialised access techniques. Offshore rope access services began developing as engineers recognised that workers needed safe, efficient methods to reach every corner of these complex structures. The techniques evolved from mountaineering and caving practices, adapted specifically for industrial applications where precision and safety were paramount.

The Piper Alpha Turning Point

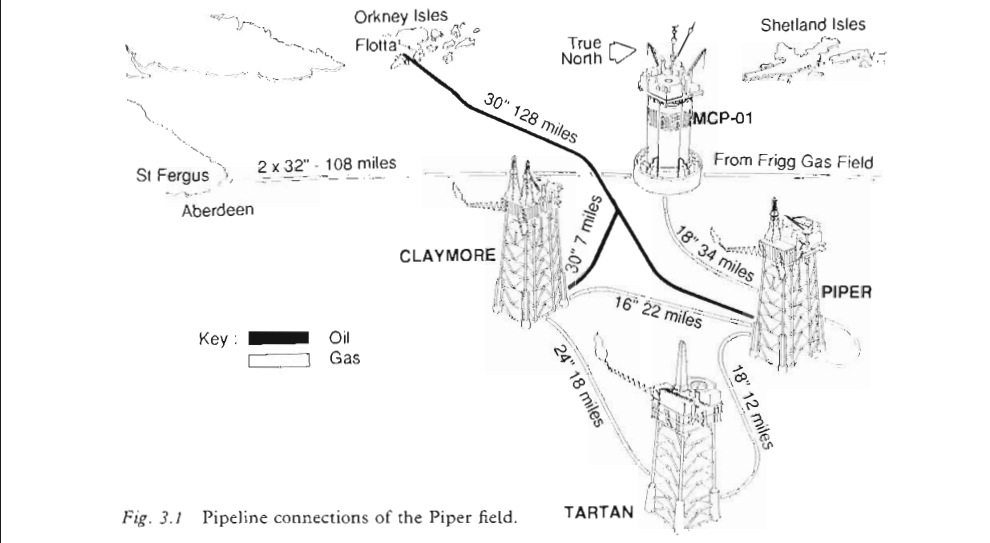

July 6, 1988, marked a watershed moment that forever changed offshore safety culture. The Piper Alpha platform disaster claimed 167 lives and became the worst offshore oil accident in history. The catastrophic explosion and fire, caused by a communication failure during routine maintenance, sent shockwaves through the entire industry.

The disaster began with a seemingly minor maintenance issue—a safety valve removal that wasn’t properly communicated between shifts. When the night crew attempted to restart a pump without knowing the valve had been removed, high-pressure gas escaped and ignited. The resulting explosion destroyed safety barriers designed only for fires, not explosions, leading to a cascading series of failures.

- Communication breakdowns: Shift changes weren’t properly documented, leading to critical information gaps

- Inadequate safety systems: Firewalls couldn’t withstand explosive forces

- Emergency response failures: Evacuation procedures proved insufficient for the disaster’s scale

- Design flaws: The platform’s layout brought dangerous operations too close to personnel areas

The Piper Alpha inquiry, led by Lord Cullen, produced over 100 safety recommendations that transformed industry practices. These changes established the foundation for modern offshore safety management, including requirements for comprehensive risk assessments and emergency procedures.

Modern Safety Standards Evolution

The post-Piper Alpha era witnessed unprecedented safety improvements across the oil and gas sector. The UK introduced the Safety Case Regulations, which require operators to demonstrate their ability to manage major hazards before commencing operations. This shifted responsibility from prescriptive rules to comprehensive risk management.

Building surveying and inspection practices underwent significant evolution during this period. Regular structural assessments became mandatory, requiring specialised techniques to examine every component of offshore installations. Traditional methods proved inadequate for the complex geometries and harsh environments of modern platforms.

IRATA (Industrial Rope Access Trade Association) was formed in the early 1980s, initially focusing on the maintenance of offshore platforms. The organisation developed standardised training and certification programs that established rope access as a legitimate industrial discipline. These standards ensured consistent safety practices across the industry while enabling access to previously unreachable areas.

Technology also played an increasingly important role in safety improvements. Digital monitoring systems, automated shutdown procedures, and advanced fire suppression systems all contributed to creating safer working environments. However, human factors remained crucial–proper training, communication, and adherence to procedures became the backbone of effective safety management.

Rope Access: A Safety Revolution

The development of industrial rope access techniques represented a fundamental shift in how the oil and gas industry approached high-risk maintenance tasks. Unlike traditional methods that required extensive scaffolding or crane operations, rope access offered unprecedented flexibility and safety in challenging environments.

Professional waterproofing services exemplify this evolution perfectly. Modern offshore platforms require constant attention to prevent water ingress and corrosion damage. Rope access technicians can inspect and maintain every seal, joint, and protective coating without the extensive setup times and space requirements of traditional access methods.

In terms of safety, rope access is widely regarded as one of the safest methods for working at height, thanks to its strict safety protocols and built-in redundancies. Every technician is secured by two independent rope systems, ensuring that even in the unlikely event of a failure, there is always a secondary line for protection. Comprehensive safety checks, rigorous training requirements, and industry-approved best practices further enhance security, making rope access a highly controlled and reliable approach compared to many other high-risk activities.

The technique’s versatility proved particularly valuable for offshore applications:

- Confined space access: Rope access enables work in areas where scaffolding cannot be erected

- Rapid deployment: Teams can begin work within minutes rather than days required for a traditional setup

- Minimal disruption: Operations continue normally while maintenance proceeds

- Cost effectiveness: Reduced equipment and setup costs make frequent inspections economically viable

Current Safety Culture

Today’s oil and gas industry bears little resemblance to its dangerous early days. Modern safety management systems integrate multiple layers of protection, from design and engineering controls to procedural safeguards and emergency response capabilities. The transformation represents one of the most successful industrial safety improvements in history.

Continuous improvement drives current safety efforts. Companies invest heavily in training, equipment, and procedures that exceed regulatory requirements. The goal has shifted from merely preventing accidents to creating positive safety cultures where workers actively participate in identifying hazards and managing risks.

International cooperation has standardised safety practices across the global industry. Organisations like IRATA ensure consistent training and certification standards, while regulatory bodies share best practices and lessons learned from incidents. Such a collaborative approach prevents the isolation that once allowed dangerous practices to persist.

Conclusion

The oil and gas industry’s safety journey from its perilous beginnings to today’s sophisticated systems demonstrates how catastrophic failures can drive positive change. The Piper Alpha disaster, despite its tragic cost, catalysed improvements that have saved countless lives over the past three decades.

Modern rope access techniques represent the culmination of this safety evolution, combining technological advancement with rigorous training and proven procedures. These methods enable the industry to maintain its complex infrastructure safely while protecting the workers who keep our energy systems operational.

The transformation from those early fearless workers to today’s highly trained safety professionals reflects the industry’s commitment to continuous improvement and worker protection.