When industrial structures require intensive surface preparation, combining rope access techniques with dry abrasive blasting creates an unbeatable solution. This powerful partnership has transformed how professionals approach challenging high-altitude projects, from the surface cleaning of urban skyscrapers to the maintenance of oil and gas rigs.

Continue reading to explore how this specialised combination delivers superior results whilst maintaining the highest safety standards.

Understanding Rope Access Technology in Industrial Cleaning

Rope access provides technicians with unprecedented mobility when working at height, eliminating the constraints and costs associated with traditional scaffolding systems. The technique allows professionals to position themselves precisely where surface preparation work is needed, creating optimal conditions for dry abrasive blasting operations.

The flexibility rope access affords is critical when dealing with complex architectural features or industrial equipment where conventional access methods prove impractical. Technicians can navigate around obstacles, reach confined spaces, and maintain consistent working positions throughout lengthy operations.

Modern rope access equipment also integrates seamlessly with specialised blasting gear, requiring extensive training and certification to ensure operators understand both IRATA safety protocols and proper abrasive techniques.

The Science Behind Dry Abrasive Blasting Techniques

Dry abrasive blasting employs high-pressure air to propel abrasive media against surfaces, effectively removing rust, old coatings, and contaminants without introducing moisture into the process. It is particularly valuable for preparing surfaces that will receive protective coatings, as the dry process eliminates concerns about trapped moisture compromising adhesion.

Different abrasive media serve specific purposes depending on the surface material and desired finish profile:

- Aluminium oxide for general-purpose cleaning and surface profiling

- Steel grit for heavy-duty rust and scale removal

- Glass beads for delicate surfaces requiring gentle treatment

- Copper slag for aggressive cleaning applications

Proper containment systems prevent the dispersion of abrasive media whilst capturing debris and contaminants. This becomes crucial when working on occupied buildings or environmentally sensitive locations, where dust control directly impacts project viability.

Safety Protocols for Elevated Blasting Operations

Combining rope access with abrasive blasting introduces unique safety considerations requiring comprehensive planning and specialised equipment. Personal protective equipment must address both fall protection and respiratory hazards, creating layered safety systems throughout operations.

Respiratory protection becomes critical during elevated blasting, where air quality can deteriorate rapidly in confined or poorly ventilated areas. Research indicates that fine particles generated during blasting pose serious risks to lung health. When abrasive blasting is used to remove lead-based paint from steel infrastructure, it can release lead particles, which are known to affect the nervous system. To mitigate these hazards, advanced filtration systems and supplied-air respirators provide safe breathing conditions, ensuring protection regardless of wind patterns or surrounding structures.

Equipment redundancy forms another cornerstone of safety. Backup rope systems, emergency communication devices, and rescue protocols provide multiple protection layers should primary systems fail. Regular inspections and maintenance schedules prevent equipment-related incidents that could compromise technician safety and project timelines.

Quality Control and Surface Preparation Standards

Professional abrasive blasting operations must achieve specific surface cleanliness and profile standards to ensure protective coating adhesion and performance. Surveying services often include photographic documentation of surface conditions before and after treatment, providing clients with work quality verification.

Surface profile measurement becomes critical for applications requiring specific anchor patterns:

- portable profile gauges verify surface roughness parameters

- replica tape confirms the required texture across treated areas

- environmental monitoring ensures compliance with regulations

- waste management protocols enable responsible disposal

Quality control extends beyond immediate surface preparation to include comprehensive environmental monitoring and proper containment system performance verification.

Applications Across Different Industries

The versatility of rope access dry abrasive blasting makes it invaluable across numerous sectors.

Offshore installations is one of the most demanding applications. Salt spray, constant weather exposure, and challenging access conditions make traditional maintenance approaches extremely difficult. Rope access teams can reach critical areas for corrosion removal without disrupting ongoing operations.

Urban environments present different challenges with noise restrictions, limited space, and occupied buildings requiring careful project planning. High-level painting services often follow abrasive blasting operations, with technicians seamlessly transitioning between surface preparation and protective coating phases.

Economic Benefits and Market Growth

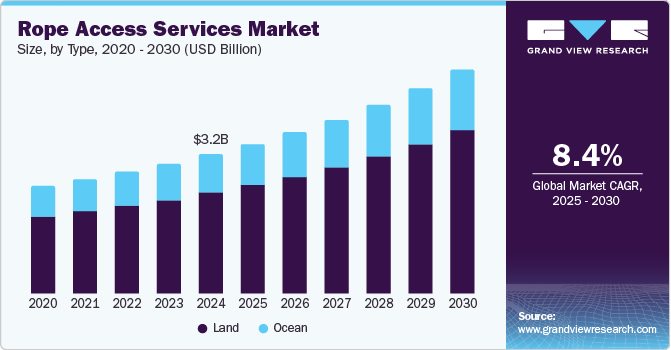

The global rope access services market size was estimated at USD 3.24 billion in 2024 and is expected to reach USD 3.47 billion in 2025, reflecting growing recognition of its economic advantages.

Traditional scaffolding systems require significant setup time, ongoing rental costs, and eventual dismantling expenses that dramatically inflate project budgets. In contrast, rope access teams begin productive work immediately upon arrival, eliminating weeks typically required for scaffolding installation.

Such rapid deployment is vital for emergency maintenance where structural integrity concerns demand immediate attention. The precision control available also reduces material waste and improves application quality through optimal working distances and angles.

Future Developments in the Field

Advancements in abrasive blasting technology are making rope access applications more efficient and environmentally friendly.

New systems now feature enhanced dust collection, reduced noise levels, and improved operator controls, helping minimise workplace hazards while increasing precision in high-access environments. As industries focus more on sustainability, equipment manufacturers continue to refine their designs to comply with stricter environmental regulations and reduce waste production.

Automation is also becoming an integral part of rope access operations, with real-time monitoring systems offering continuous feedback on blasting parameters, surface conditions, and environmental factors. This helps technicians adjust their approach as needed, ensuring optimal results while maintaining safety. As technology progresses, remote-controlled blasting equipment and robotic assistance could complement human teams, handling routine tasks while technicians focus on complex inspections and adjustments.

The integration of smart technology in rope access is likewise expanding. Digital tracking and reporting tools provide detailed insights into project efficiency, material usage, and surface integrity.

These innovations are shaping the future of rope access applications, allowing businesses to streamline operations while upholding high safety and environmental standards.

Conclusion

Combining rope access techniques with dry abrasive blasting offers a practical and effective solution for industrial surface preparation, particularly in challenging environments. This approach enhances mobility, precision, and safety, making it well-suited for complex maintenance projects where traditional methods may be impractical or costly.

Beyond its technical advantages, rope access dry abrasive blasting provides economic benefits, reducing setup time and minimising disruption to ongoing operations. As industries increasingly adopt this method, it is set to play a key role in maintaining critical infrastructure and industrial assets, while upholding high safety standards and operational efficiency